- Home

- Products

- Crossflow Cooling Tower

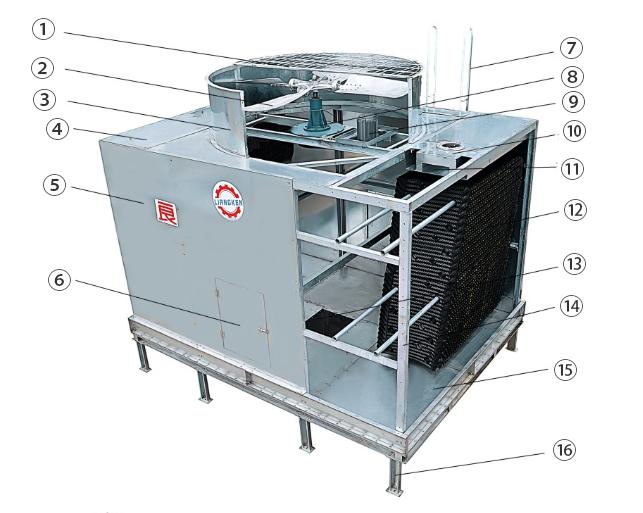

- Crossflow Cooling Tower (Open Circuit Steel Cooling Tower)

Crossflow Cooling Tower (Open Circuit Steel Cooling Tower)

General heat-rejection devices are placed on building rooftops. However, because this crossflow cooling tower is ideal for special environments, it can be installed in middle building floors. A fan exhaust structure is used, as air enters from one side and exits on the other. With its installation in the middle of the building, the system also saves energy. Water flows slowly down the PVC fillings, thus controlling noise and ensuring noise remains at low levels.

The hot water in the crossflow cooling tower travels through the distribution basin and falls uniformly on the PVC film sheets which then absorb heat and further evaporate the water in large areas. An efficient fan installed at the top then draws in cold air from outside, brings it into contact with hot water, and ensures the heat exchange process happens for water evaporation. In doing so, the water temperature is reduced for water recycling.

1. Fan Guard

2. Fan

3. Fan Stack

4. Distribution Cover

5. Casing

6. Access Door

7. Ladder

8. V-Belt Reducer

9. Motor

10. Distribution Box

11. Hot Water Basin

12. Infill

13. Suction tank

14. Frame

15. Basin

16. Low Frame

Frame

The entire tower body of the evaporative cooling system is designed with an all-steel structure, which is recyclable and generates no pollution. This makes it an environmentally friendly evaporative cooling product.

Motor

The open-circuit heat-rejection equipment is equipped with a fully totally enclosed motor, which features an IP55 waterproof grade and corrosion resistance, making it suitable for cooling towers used in high temperature and highly humid environments.

Fan

The fan is made of aluminum alloy and designed with wide twisted blades, thus featuring a large air volume and low noise when running at low speeds.

Fill media

Low wind-resistance PVC hanging fill sheets allow for a high heat transfer efficiency and electric energy saving.

- Guardrail

- 304/316 stainless steel frame

- High temperature accessories

- Gear reducer

- Shock absorber and two-speed motor