Cooling Tower Components

Liangken provides various components for evaporative cooling towers, such as motor gear unit, air inlet louver, film fill and pumps.

-

- Cooling Tower Motor Gear Unit Located at the top of the cooling tower is the fan deck that houses the motor (or motor + gear unit) that works in conjunction with the fan and fan assembly. The motor is the most important component of the cooling tower as it drives all other parts to effectively remove heat from the facilities.

-

- Water Distribution System The water distribution system is installed between the drift eliminator and fill media in the tower. It distributes hot water by evenly spraying it on the fill media in the tower. The sprinkler device features a large-diameter ELLERT-type sprinkler head made of corrosion resistant polyvinyl chloride (PVC).

-

- Air Inlet Louver Installed near the cold water basin on the outside of the tower body, the air inlet louver draws air into the tower. The stainless steel air inlet louver features a special design tilted towards the inside to prevent the sprinkled water from side leakage. It can also prevent dust accumulation and direct sunlight.

-

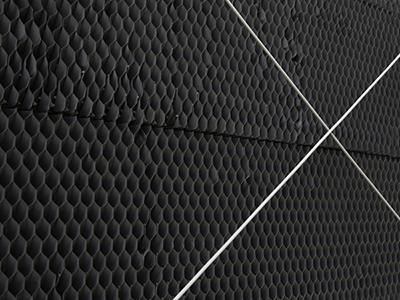

- Cooling Tower Fill The cooling tower fill forms the heat transfer surface needed for the heat exchange between the water and air in the cooling tower. Its performance is significantly greater than PP fillings due to its larger heat exchange surface area. This helps to effectively prevent water from spilling out of the water basin and thus, saving water.

-

- Cooling Tower Pumps Cooling tower pumps are installed to deliver clean water to the spray system installed in the tower. Spray water pumps are all customized according to the characteristics of the cooling towers and they feature a large flow and low spray head.