- Home

- Products

A cooling tower is heat removal device that uses water to transfer process waste heat into the atmosphere. Cooling towers are well recognised as special type of heat exchangers that commonly used in HVAC and industrial applications.

We understand different types of cooling tower units manufacturing:

Cooling Tower Working Principle

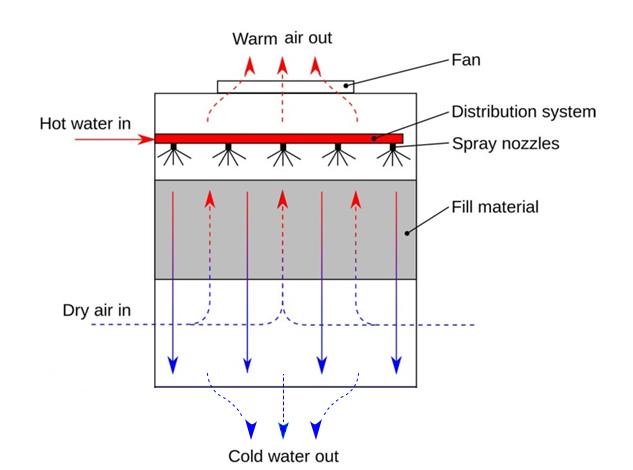

Evaporative cooling is the process, where warm water from an HVAC system/industrial process is pumped up to the top of the cooling tower, while the water gets distributed by cooling tower nozzles to the wet deck. At the same time, air is being drawn through the air-inlet louvers forcing water to evaporate. Evaporation causes the heat away from the cooling towers and into the atmosphere.

During the operation of some processing equipment, water temperature will rise significantly. When this happens, bringing in new cold water is an effective method but wastes resources, thus the evaporative cooling tower was developed. The cooling tower utilizes a circulating water cooling method to obtain the highest level of heat exchange efficiency possible, greatly saving energy resources. Using circulating water as the media, the evaporative cooling tower uses the principle of water evaporation that absorbs heat to take away the transferred heat from the air conditioning systems of buildings and the wasted heat generated from processing equipment in industrial manufacturing. Evaporative cooling towers are typically used in combination with air conditioning systems, air compressors, injection molding machines, and other HVAC systems. An effective cooling tower can be made depending on the following factors: material of the casing, heat dissipation fill media, fan, motor, and structural design.

- Evaporative Cooling Tower

- Cooling Tower Pumps

- Cooling Tower Components

Guangdong Liangken Cooling Equipment Co., Ltd.

Contact Person: Mr. Zhou

Tel.: +86-0769-85537162

+86-0769-85313501

Fax: +86-0769-83126345